US12504263 - Seating die

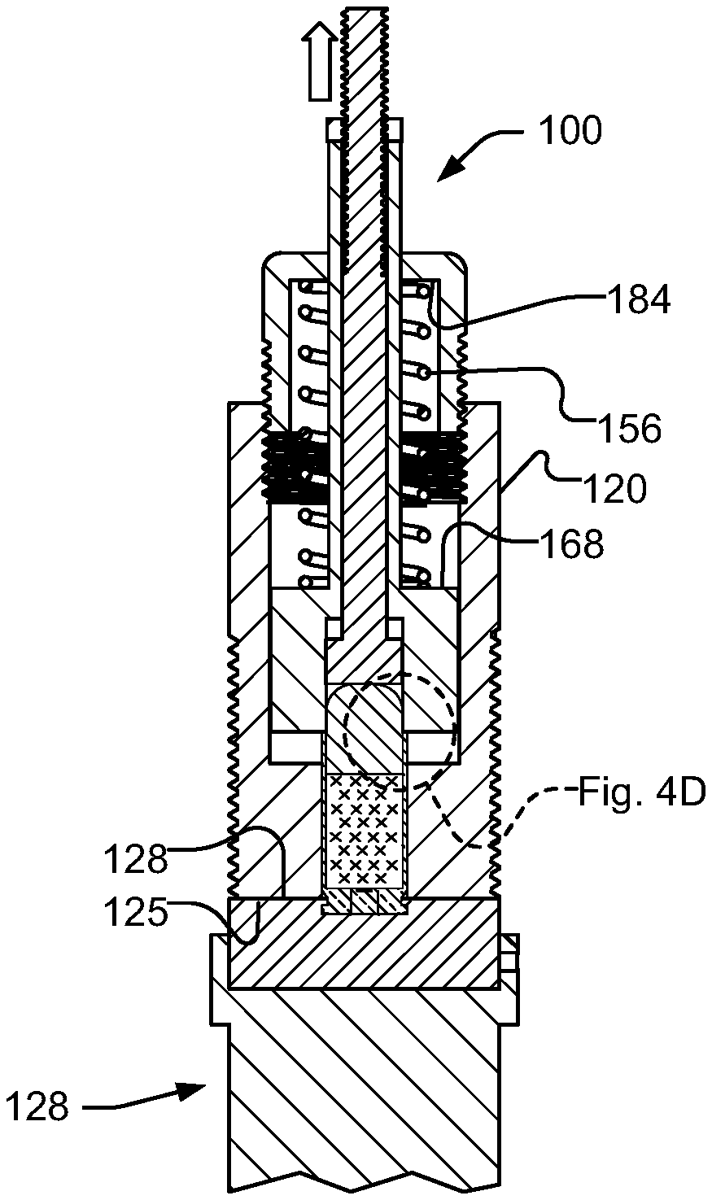

The patent describes a seating die assembly designed for reloading ammunition, featuring a die body with an elongated cavity and a cartridge receiver that facilitates the seating of a bullet into a casing. A top punch, urged by a biasing element, translates within the cavity to ensure precise bullet seating depth as the casing is moved into position.

Claim 1

1 . A seating die assembly comprising: a die body comprising: a longitudinal axis; a first end surface and a second end surface opposing the first end surface, the first and second end surfaces separated from each other along the longitudinal axis; an elongated cavity disposed along the longitudinal axis; a cartridge receiver defining an opening on the first end surface connected to the elongated cavity; a top punch for seating a bullet in a casing disposed at least partially within the elongated cavity and translatable within the elongated cavity along the longitudinal axis, wherein the top punch includes a bottom surface; a biasing element disposed within the elongated cavity for urging the top punch toward the cartridge receiver to seat the bullet in the casing; and a seating sleeve disposed at least partially within the elongated cavity and comprising a punch passage and having a bottom surface, wherein the bottom surface of the seating sleeve and the bottom surface of the top punch are separated by a distance along the longitudinal axis, wherein, when a cartridge holder assembly holding a casing having a top edge and containing a bullet having a top portion is moved into the cartridge receiver, the top portion of the bullet engages the bottom surface of the top punch such that the bullet is pushed into the casing until the top edge of the casing engages the bottom surface of the sleeve thereby causing the motion of the casing relative to the bullet and the cartridge receiver to stop so that the distance determines a bullet seating depth of the bullet in the casing. a die body comprising: a longitudinal axis; a first end surface and a second end surface opposing the first end surface, the first and second end surfaces separated from each other along the longitudinal axis; an elongated cavity disposed along the longitudinal axis; a cartridge receiver defining an opening on the first end surface connected to the elongated cavity; a top punch for seating a bullet in a casing disposed at least partially within the elongated cavity and translatable within the elongated cavity along the longitudinal axis, wherein the top punch includes a bottom surface; a biasing element disposed within the elongated cavity for urging the top punch toward the cartridge receiver to seat the bullet in the casing; and a seating sleeve disposed at least partially within the elongated cavity and comprising a punch passage and having a bottom surface, wherein the bottom surface of the seating sleeve and the bottom surface of the top punch are separated by a distance along the longitudinal axis, wherein, when a cartridge holder assembly holding a casing having a top edge and containing a bullet having a top portion is moved into the cartridge receiver, the top portion of the bullet engages the bottom surface of the top punch such that the bullet is pushed into the casing until the top edge of the casing engages the bottom surface of the sleeve thereby causing the motion of the casing relative to the bullet and the cartridge receiver to stop so that the distance determines a bullet seating depth of the bullet in the casing. a longitudinal axis; a first end surface and a second end surface opposing the first end surface, the first and second end surfaces separated from each other along the longitudinal axis; an elongated cavity disposed along the longitudinal axis; a cartridge receiver defining an opening on the first end surface connected to the elongated cavity; a top punch for seating a bullet in a casing disposed at least partially within the elongated cavity and translatable within the elongated cavity along the longitudinal axis, wherein the top punch includes a bottom surface; a biasing element disposed within the elongated cavity for urging the top punch toward the cartridge receiver to seat the bullet in the casing; and a seating sleeve disposed at least partially within the elongated cavity and comprising a punch passage and having a bottom surface, wherein the bottom surface of the seating sleeve and the bottom surface of the top punch are separated by a distance along the longitudinal axis, wherein, when a cartridge holder assembly holding a casing having a top edge and containing a bullet having a top portion is moved into the cartridge receiver, the top portion of the bullet engages the bottom surface of the top punch such that the bullet is pushed into the casing until the top edge of the casing engages the bottom surface of the sleeve thereby causing the motion of the casing relative to the bullet and the cartridge receiver to stop so that the distance determines a bullet seating depth of the bullet in the casing.

Google Patents

https://patents.google.com/patent/US12504263

USPTO PDF

https://image-ppubs.uspto.gov/dirsearch-public/print/downloadPdf/12504263